| Sign In | Join Free | My wpc-board.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My wpc-board.com |

|

Place of Origin : Guangdong

MOQ : 1

Brand Name : Lion King

Certification : CE

Delivery Time : 20

Packaging Details : wooden box packaging

Coating Adhesion : ≥Grade 0

Coating Temperature : ≤150℃

Coating Material : Low Emissivity Glass

Glass Type : Emissivity Glass

Emissivity : Low

Coating Durability : Long-lasting

Coating Speed : ≤10m/min

Coating Type : Vacuum Coating

Application : Glass Coating

Coating Uniformity : ±5%

Coating Method : Sputtering

Coating Transparency : ≥80%

Coating Efficiency : High

Coating Size : Customized

Coating Substrate : Glass

Coating Resistance : ≥1000 hours of salt spray test

Coating Application : Low-E Glass, Architectural Glass, Automotive Glass

Coating Hardness : ≥6H

Coating Technology : Vacuum Coating

Coating Thickness : 5~15nm

Target : silver

Coating Adhes : 3~10 N/mm²

Coating Temperature Resistance : 100~200°

Coating Color : Silver/Gray

Coating Lifespan : ≥10 years

Coating Equipment Dimension : Customized according to customer's requirements

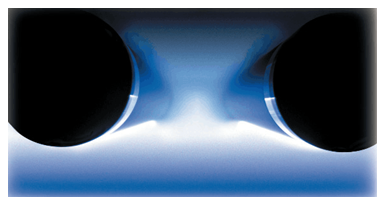

The rotary sputter cathode has many advantages compared with planar sputter cathode, such like:

Higher utilization rate of target material

Higher applicable sputter power and increasing of sputter rates

Stability working in AC power supply (less arcing and poisoning)

Flexibility in target materials including metal, metal oxide and ceramic targets

Therefore the dual rotary cathode is the best selection of Low-E glass magnetron sputtering line for oxide and semi-conductive layers.

Lion King can design and manufacture the dual rotary sputter cathode for our customers. There are ten sets of Low-E coating machine had equipped with Goldstone’s rotatable cathodes for the past 22 years

|

|

Horizontal Large Scale Low E Glass Vacuum Coating Line Glass Magnetron Sputtering Coating Images |